Professional, affordable installation helps extend the lifespan of your windows.

Outline

1) Understanding When to Replace vs. Repair

2) Materials and Glazing Options: Matching Performance to Climate

3) Installation Methods and Quality Assurance: What Professionals Do

4) Cost, Financing, and Long‑Term Value

5) Choosing a Window Replacement Service: Contracts, Warranties, and Aftercare

Understanding When to Replace vs. Repair

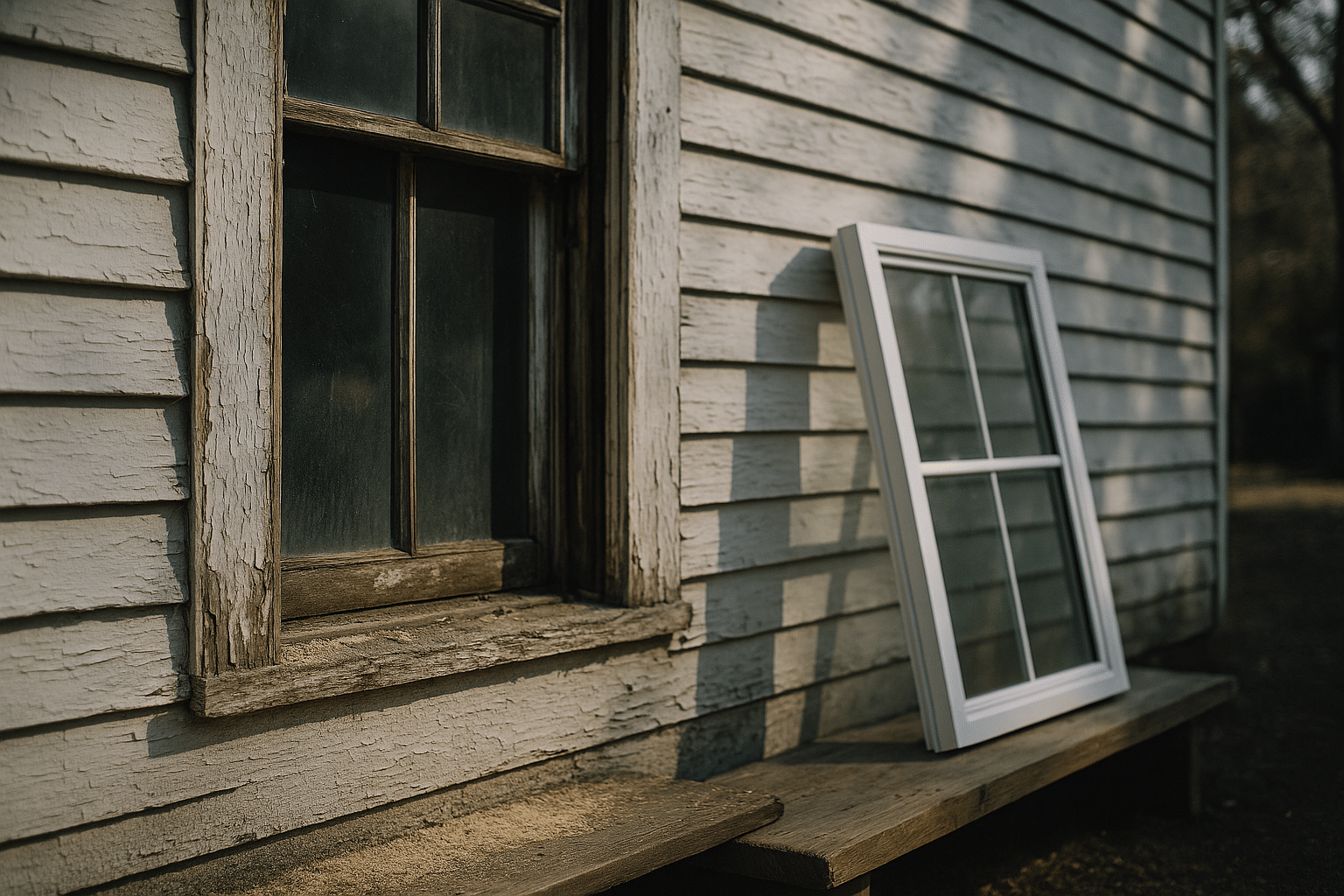

Windows quietly shape how a home feels, breathes, and spends. Deciding whether to repair or replace them calls for clear-eyed evaluation rather than guesswork. A good rule of thumb: if issues compromise structural integrity, safety, or energy performance, a strategic replacement often pays back in comfort and reduced utility costs. In many homes, heat gain and loss through windows can account for roughly a quarter to a third of heating and cooling energy use, so addressing leaky frames and outdated glass can make a noticeable difference. But replacement is not the only path; minor concerns—like a failed lock, a worn weatherstrip, or a cracked exterior bead of caulk—can be repaired. The skill lies in separating cosmetic problems from performance failures.

Look for patterns rather than isolated symptoms. Tell-tale signs you may need replacement include:

– Drafts you can feel on windy days, even with sashes closed and latched

– Persistent condensation or fogging between panes (indicative of a failed seal)

– Soft, spongy, or warped frames and sills that suggest moisture damage

– Sticking sashes caused by swelling, frame distortion, or hardware fatigue

– Noticeable street noise infiltration and fading furnishings from high UV exposure

– Water stains on interior trim that return after re-caulking

– Safety or egress concerns in sleeping areas due to window size or function

Repair is sensible when the frame is sound, glass is intact, and the issue is localized. For example, adjusting balances to restore smooth operation, reapplying high-quality sealant, adding new weatherstripping, or replacing a cracked pane can extend service life at modest cost. Replacement becomes compelling when multiple failures coincide—such as deteriorated frames, repeated water intrusion, and failed insulated glazing. Also consider your broader goals: if you are targeting energy savings, improved acoustics, or modern ventilation features, new units with low-emissivity coatings, gas fills, and tighter tolerances can elevate performance beyond what repairs can deliver. Think of windows as a system interacting with walls, siding, insulation, and HVAC; once the window’s weakest links outnumber the quick fixes, a planned replacement stops small leaks from becoming large bills.

Materials and Glazing Options: Matching Performance to Climate

Frame material influences durability, maintenance, thermal performance, and curb appeal. Vinyl provides strong value and low upkeep; it resists moisture and does not need painting, though extreme temperature swings can cause slight movement, and color choices may be limited. Wood offers a timeless look, excellent stiffness, and good insulating properties; it does require periodic finishing or cladding to fend off moisture. Fiberglass is dimensionally stable, resists expansion and contraction, and accepts paint; its rigidity supports larger openings with minimal frame bulk. Aluminum is slim and strong, well-suited to large spans in mild climates; thermal breaks are essential to reduce conductivity in cooler regions. Composites blend materials to balance strength, efficiency, and upkeep. The right choice hinges on climate, architectural style, and how much maintenance you are willing to perform.

Glazing dictates energy behavior. Double-pane insulated glass is the current baseline; triple-pane can add comfort in cold or noisy areas by improving insulation and sound damping. Low-emissivity (low‑e) coatings reflect infrared heat while letting in visible light; pairing low‑e with argon or krypton gas fills further curbs conductive and convective heat transfer. Key metrics to compare include:

– U-factor: lower values mean better insulation, important in colder climates

– Solar Heat Gain Coefficient (SHGC): lower values block more solar heat; choose higher SHGC for passive winter gains or lower SHGC for hot, sunny regions

– Visible Transmittance (VT): higher values let in more daylight, improving interior brightness

Climate-smart combinations pay off. In northern zones, prioritize low U-factor and consider triple-pane in rooms where comfort is paramount, like bedrooms and family areas. In hot, sun-baked regions, pair low SHGC with spectrally selective coatings to reduce solar gain without overly dimming the room. Along noisy streets or flight paths, laminated glass or asymmetric panes can lower perceived noise by several decibels, making interiors feel calmer. Don’t overlook spacers between panes: warm-edge spacers reduce condensation risk at glass edges. Finally, verify that the chosen frame and glazing package together meet your goals. For instance, a well-insulated frame with high-VT, low-SHGC glass can deliver a bright, cool interior in summer while preserving winter comfort—proof that small component choices add up to major daily benefits.

Installation Methods and Quality Assurance: What Professionals Do

Even the most efficient window underperforms if it is installed without proper water management and air sealing. Professionals typically choose between insert (retrofit) installation and full-frame replacement. Insert installations preserve existing frames and interior trim, minimizing disruption and cost; they’re ideal when frames are square, solid, and water-tight. Full-frame replacement removes everything down to the rough opening, allowing pros to correct flashing errors, rot, and insulation gaps; it’s the right call when existing frames are damaged or when you want to change size, style, or operation. Either route hinges on meticulous preparation and methodical execution.

Here is what a thorough process commonly includes:

– Precise measurement and verification of squareness, plumb, and level

– Careful removal of sashes and stops, with dust control and surface protection

– Inspection of the opening, including probing sills for hidden rot and checking for past water paths

– Integration of sill pans or formed flashing to funnel any incidental water outward

– Dry-fitting the unit, shimming at structural points, and confirming reveals are even

– Fastening per manufacturer specifications, avoiding frame distortion

– Air sealing with low-expansion foam or backer rod plus high-quality sealant

– Integrating exterior flashing tape with existing weather-resistive barriers

– Adding a drip cap where appropriate to shed water away from the head jamb

– Verifying operation, weep paths, and hardware function before final trim and paint

Quality assurance does not end at the last bead of caulk. A conscientious installer checks that sashes lock smoothly, screens fit, and gap tolerances are uniform. On exteriors, sealant joints should be tooled for proper adhesion and drainage, not merely smeared. Indoors, foam should not over-expand and bow the frame; shims should remain where load-bearing, not be removed after fastening. Older homes may require lead-safe work practices when disturbing painted components; ask for compliance with relevant laws for pre-1978 construction. Expect a walkthrough: you should see clean sightlines, consistent operation, and documentation on care and maintenance. In performance-focused projects, some teams also coordinate blower-door tests to confirm reduced air leakage. Good installation is equal parts craft and building science—quietly preventing the water and air you do not want while welcoming daylight, views, and breezes on your terms.

Cost, Financing, and Long‑Term Value

Window replacement costs vary widely based on material, glazing complexity, size, and installation scope. Insert installations often cost less than full-frame projects because they preserve existing trim and siding interfaces. Larger openings, custom shapes, specialty coatings, laminated glass for acoustics, and upgraded hardware add to the budget. Labor is influenced by access (upper floors and scaffolding), discovery of rot or framing corrections, and local wage conditions. A practical way to think about cost is as a range per opening, then refine with an on-site assessment. While exact figures depend on region and scope, many homeowners plan with a tiered mindset: a value tier for standard openings and rooms used less often, a performance tier for spaces needing extra comfort or quiet, and a premium tier for signature rooms or design impacts.

Total value extends past the invoice. Energy-efficient units paired with tight installation can trim heating and cooling demand, especially when replacing leaky single panes. Depending on climate and existing conditions, reductions in HVAC runtime can accumulate into meaningful savings over time. Upgrades also provide comfort benefits not fully captured on a utility bill: warmer interior glass temperatures reduce radiant chill in winter, while optimized solar control can tame summer hotspots. Acoustic glazing can lower outside noise by several decibels, improving sleep quality and focus. Safety glazing near doors and bathing spaces, egress-compliant bedrooms, and smooth-locking hardware add everyday peace of mind.

To keep projects manageable, consider:

– Phasing: tackle the draftiest elevations first to capture early comfort gains

– Bundling: group similar sizes to improve ordering efficiency and reduce waste

– Incentives: check for local utility or municipal rebates and possible tax advantages

– Financing: explore low-rate options through credit unions or home-improvement lenders

– Life-cycle costs: include repainting, refinishing, and routine maintenance in your forecast

Run a simple payback check: estimate annual energy savings, assign a dollar value based on your utility rates, and compare against project cost. While payback periods vary, many households value the combined package—lower bills, quieter rooms, easier operation, and refreshed appearance—rather than chasing a single metric. Keep contingencies in the budget (often 10–15%) for hidden issues like sill rot or outdated flashing. Clear scope, realistic allowances, and honest communication prevent surprises and protect both performance and pocketbook.

Choosing a Window Replacement Service: Contracts, Warranties, and Aftercare

Selecting the right service provider is as important as choosing the window itself. Look for a track record of quality installations, consistent communication, and documentation that stands up over time. Credentials matter: proper licensing where required, liability and workers’ compensation insurance, and training in weather barrier integration. References should include recent jobs and projects older than five years so you can see how work ages. Ask to view sample details—sill pans, flashing sequences, and sealant joints—because performance is built at these intersections, not just in the showroom.

Use a structured interview and proposal review:

– Request a written scope describing removal, repair of discovered rot, flashing, insulation, and sealant methods

– Confirm whether the project is insert or full-frame and why that approach suits your home

– Clarify lead times, delivery windows, and how the team will protect floors, landscaping, and furnishings

– Verify cleanup, disposal, and recycling of old units where possible

– Ask for both product and labor warranties, with terms, transferability, and claim process in writing

– Ensure compliance with lead-safe practices for older homes when applicable

Strong contracts reduce friction. They name materials, glass specs, color, grid patterns, jamb depths, hardware finishes, and any custom trim. They identify who patches interior walls, repaints trim, or replaces exterior casing if removal reveals hidden issues. Payment schedules should follow milestones—such as deposit, delivery, and completion—rather than front-loading the majority of cost. During installation, expect a daily check-in, photos of concealed steps (like flashing integration) for your records, and a final walkthrough demonstrating operation, ventilation settings, and maintenance basics. Aftercare matters: keep weep holes clear, inspect sealant joints annually, wash gently to protect coatings, and operate sashes a few times a year to keep balances free.

Red flags include vague scopes, unwillingness to discuss flashing details, pushy sales tactics that ignore your climate or house design, and quotes that are dramatically lower without a clear explanation of cause. On the other hand, a well-organized team will listen first, tailor recommendations to your goals, and deliver a transparent proposal. With the right partner, replacement feels less like a disruptive project and more like giving your home a new set of clear, finely tuned lenses—quietly improving comfort, efficiency, and curb appeal for years to come.

Putting It All Together: A Practical Roadmap for Homeowners

Successful window projects follow a simple sequence: assess, prioritize, specify, and verify. Start with a walk-through on a breezy day, noting drafts, condensation, stuck sashes, and noisy rooms. Rank rooms by discomfort and energy loss; this prioritization helps you phase work if needed. Define your objectives—energy savings, glare control, ventilation, noise reduction, or style—and translate them into performance criteria: target U-factor and SHGC bands, desired visible transmittance, and frame material preferences. With objectives in hand, request quotes that mirror the same specifications so comparisons are apples-to-apples. A good proposal balances performance with aesthetics and maintenance demands.

During selection, pressure-test assumptions. For a cold, windy site, will triple-pane in living areas bring tangible comfort gains relative to cost? For a sunny façade, could a low SHGC with high visible transmittance preserve daylight while taming heat gain? For a home near traffic, would laminated glass in bedrooms deliver the quiet you want without reworking the entire house? Also consider detailing: warm-edge spacers, robust corner joinery, and durable exterior finishes extend service life. Finally, look beyond single features and evaluate the whole system—frame, sash, glass, sealants, and flashing—because durability is decided by how well the pieces work together when the weather is unkind.

As you move to contract and installation, confirm logistics:

– Scheduling: align delivery, crew availability, and your calendar; avoid forecasted storm days

– Site prep: clear furniture, take down window treatments, and create safe pathways

– Protection: floor runners, dust control, and careful removal of trim where reused

– Documentation: keep spec sheets, warranty terms, and photos of flashing steps

– Sign-off: operate every unit before the crew leaves; check locks, latches, and weep paths

After project closeout, set a maintenance calendar. Seasonal checks for sealant adhesion, blocked weeps, and paint condition catch little issues before they bloom. Clean glass with a mild solution, avoid harsh abrasives on coated surfaces, and gently vacuum tracks. On a cool evening, try the “candle test” by holding a flame near trim to sense drafts—if the flame wavers, call your installer to adjust weatherstripping or add sealant where needed. Over time, these habits keep your windows performing like day one. Thoughtful planning, steady communication, and detail-driven installation transform replacement from a leap of faith into a measured step toward a quieter, more efficient, and more comfortable home.

Conclusion

For homeowners weighing window replacement, clarity beats hype. Define your goals, compare materials and glazing by climate, and choose a service provider who builds performance into every detail. With a phased plan and a quality installation, you can elevate comfort, lower energy use, and refresh your home’s look without derailing your budget. The right windows, installed with care, become a long-lasting upgrade you notice in every season.