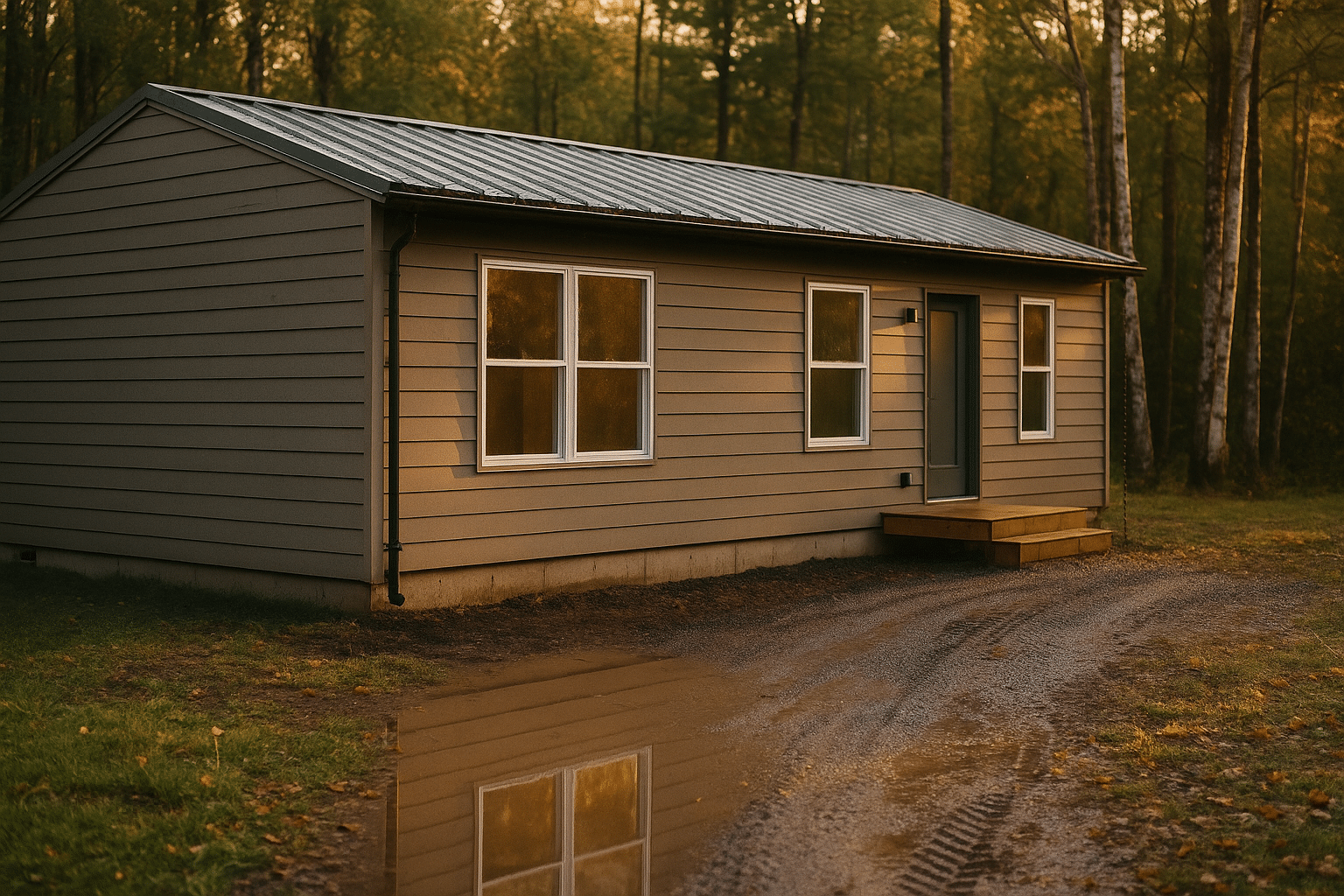

Modern prefabricated houses: Comfort and affordability combined

Why Prefab Now? Definitions, Context, and an Outline

Housing is evolving fast, and the gap between dream and doorway often comes down to time, cost, and certainty. Prefabrication—building components in a controlled factory, then assembling them on-site—responds to all three. It shortens construction calendars, stabilizes quality, and reduces material waste. At the same time, design has matured: today’s homes can be warm, flexible, and climate-aware rather than boxy or bland. To set the stage, here’s a quick outline of what follows before we dig into the details:

– What prefab means today and how it works

– Design, materials, and performance benchmarks

– Costs, timelines, and long-term value

– Customization and use cases across climates

– A practical buyer checklist and conclusion

Let’s clarify the core vocabulary. Prefabrication includes several approaches: panelized systems (walls, floors, and roof panels shipped flat), modular units (three-dimensional volumes craned into place), and hybrid methods that mix factory-made shells with site-built interiors. The common thread is off-site precision that aims to minimize weather delays, labor bottlenecks, and on-site rework. This industrial logic is not about removing craft; rather, it relocates craftsmanship to a setting where tools, jigs, and repeatable processes can shine. Modern prefabricated houses reflect this shift by offering predictable assembly while giving architects room to choreograph light, storage, and flow for everyday living. For households balancing budget discipline with comfort, this combination can be compelling.

Why is the moment ripe? Several forces are aligned: skilled labor shortages, rising material costs, and the need to reduce construction waste are pushing builders to rethink delivery. Factory conditions can cut off-cuts and packaging waste meaningfully, and standardized components simplify logistics. Meanwhile, digitized design-to-fabrication pipelines help catch clashes before they reach the site. The result, in many regions, is a home that arrives largely complete, settles on a prepared foundation, and reaches move-in readiness weeks or months sooner than conventional builds. In the sections ahead, we translate these promises into specifics you can evaluate.

Design, Materials, and Performance: How Prefab Achieves Comfort

Good homes feel calm, sturdy, and energy-smart. Achieving that is a technical journey that starts long before the first delivery truck arrives. Modern factories work from detailed 3D models to pre-cut framing, integrate electrical chases, and install insulation consistently. That consistency matters for drafts, noise control, and thermal comfort. Thoughtful design also avoids thermal bridges, tunes window placement for daylight, and pairs smart ventilation with tight envelopes to maintain indoor air quality without energy waste.

Materials vary by climate and budget. Wood framing remains common for its renewable profile and easy repairability. Cross-laminated timber and other engineered woods add stiffness and dimensional stability. Steel modules excel for spanning and stacking but require careful thermal breaks. Panelized systems often use high-R insulated cores that slide into precise frames, reducing on-site trimming. Windows with multi-pane glazing and low-emissivity coatings cut heat loss and glare; doors with insulated cores prevent cold edges. Roofing can integrate cool membranes or high-albedo finishes that reflect summer heat, while deep eaves provide shade and protect cladding.

– Airtightness targets in efficient projects can be several times tighter than typical code homes

– Insulation depths are sized to climate; cold regions may use thicker walls and attic blankets

– Ventilation strategies combine continuous fresh air with heat or moisture recovery for comfort

– Sound attenuation uses resilient channels and layered assemblies to soften urban noise

– Durable claddings (fiber cement, treated woods, metals) resist weather and UV

Performance is not only about energy. Resilience matters: controlled factory environments yield straight, square components that translate into better load paths and fewer squeaks. In high-wind or seismic zones, engineers specify hold-downs, shear walls, and module connectors to behave predictably under stress. Moisture management, a silent enemy, is addressed with taped air barriers, ventilated rainscreens, and flashing details executed on benches rather than ladders. The cumulative effect is a home that feels solid in the hand—doors latch cleanly, floors remain level, and corners stay crisp through seasons. When designed and assembled well, Modern prefabricated houses deliver comfort as a feature of engineering, not just aesthetics.

Costs, Timelines, and Total Value: From Budget to Move-In

Cost questions come first for most buyers, and prefab’s answer is nuanced rather than one-size-fits-all. Off-site construction can streamline labor and reduce waste, which may translate into lower or more predictable pricing. In many markets, turnkey costs land within a broad range depending on size, finishes, site conditions, and transport distance. Where savings appear, they often show up as fewer change orders, condensed timelines, and less carrying cost on financing because the home is ready sooner.

Timelines illustrate the advantage. A typical sequence might look like this: design and permitting (6–12 weeks), factory fabrication (6–10 weeks), site prep and foundation (in parallel, 3–6 weeks), set day with crane (1–3 days), then finish work and inspections (3–6 weeks). By overlapping factory work with site preparation, calendar time drops without compressing the craft. Weather exposure is minimized, especially for sensitive materials like subfloors and insulation. For many households, cutting one or two months of interim rent, storage, or loan interest is a meaningful part of the value story.

– Budget drivers: foundation type, access for trucks and crane, regional labor rates, and finish upgrades

– Hidden line items: utility hookups, permits, impact fees, soil reports, and landscaping

– Operating costs: tighter envelopes and efficient equipment can lower monthly energy bills

– Resale factors: documented specs and performance can reassure future buyers

– Maintenance: factory-applied finishes and modular parts simplify repairs

It’s helpful to think in total cost of ownership, not just sticker price. Consider energy use over 10–20 years, likely maintenance cycles, and potential retrofit ease. Some prefabricated assemblies make it simpler to replace cladding or upgrade windows later. Insurance premiums can reflect resilience measures; likewise, higher efficiency may unlock local incentives. Importantly, Modern prefabricated houses can reduce cost volatility: standardized components are less subject to on-site surprises, and fabrication slots create clearer schedules, which in turn help you plan financing and move dates with fewer unpleasant pivots.

Customization, Everyday Living, and Where Prefab Fits

Prefab is often mistaken for rigid templates, but current catalogs and custom workflows cover a spectrum—from compact studios to spacious multi-bedroom layouts, single-level living to stacked urban townhomes. The design game is about modules and panels as building blocks, which can be composed into distinct silhouettes and room sequences. Want a generous mudroom, a reading nook with afternoon light, or a kitchen that opens to a wind-sheltered deck? Those moves are available when early design aligns with structural grids and transport limits.

Site context shapes choices. Narrow urban lots may suit stacked modules with street-friendly facades, while rural plots can stretch out with long rooflines that frame views. Snowy regions benefit from steeper roofs and protected entries; hot climates lean on cross-ventilation and deep shade. Off-grid or low-grid living is realistic when design includes efficient envelopes, solar-ready roofs, and storage scaled to daily use. Accessibility can be baked in with zero-step entries, wider doorways, and reinforced bathroom walls ready for future grab bars.

– Typical add-ons: covered porches, screened rooms, integrated sheds, and carports

– Storage strategies: built-in benches, pantry walls, attic ladders, and under-stair drawers

– Flex spaces: pocket offices, convertible guest rooms, and play areas that age gracefully

– Material palettes: warm woods, quiet minerals, and durable metals that weather elegantly

– Outdoor connection: sliding doors, corner glazing, and sheltered courtyards

Lifestyle details count: acoustics that keep kids’ rooms peaceful, lighting that follows circadian rhythms, and mechanical systems sized for whisper-quiet operation. Kitchens and baths arrive with tight tolerances, so cabinetry aligns and tile grids stay true. Thoughtful zoning, like separating sleeping areas from active living, supports both daily rhythm and entertaining. Pets get durable floors and hose-friendly entries; hobbyists get sturdy walls ready for shelves. Crucially, Modern prefabricated houses accommodate future change—modules can be added, porches enclosed, or accessory dwellings introduced as families grow or household economics evolve.

Conclusion and Buyer Checklist: Turning Plans into Keys

Prefabrication is not a magic wand, but it is a practical, disciplined way to build with fewer unknowns. It trades weather delays for assembly days, rework for quality control, and guesswork for drawings that actually match what arrives. If you value comfort, clean lines, and steady budgets, the approach deserves a careful look. The goal is not speed alone; it’s a home that stays comfortable through summers and storms, and that welcomes you with low noise and even temperatures year after year.

Use this buyer checklist to move from curiosity to clarity:

– Zoning and codes: confirm what your lot allows for height, setbacks, and accessory units

– Access plan: measure road widths, turning radii, and utility clearances for delivery

– Foundation choice: slab, crawlspace, or basement, matched to soil and energy goals

– Envelope specs: target airtightness, insulation values, and window performance

– Mechanical systems: right-size heating, cooling, ventilation, and hot water

– Electrical plan: capacity for induction cooking, EV charging, and solar-ready conduits

– Finish durability: verify warranties, maintenance intervals, and repairability

– Schedule realism: align factory slot, site prep, and financing milestones

– Closeout documents: collect as-builts, manuals, and a maintenance calendar

Red flags to watch: vague specifications, unclear responsibility for site work, and schedules that don’t account for utility lead times. Ask for mockups or sample corners to see workmanship up close. Request blower-door and plumbing pressure tests to prove performance. If you’re remote from the factory, probe transport costs and set-day contingencies, like staging areas and crane availability. Above all, insist on a scope that matches your climate and lifestyle rather than chasing trends.

The promise is grounded, not grandiose: Modern prefabricated houses combine factory precision with thoughtful design to create cozy, practical dwellings. With a clear brief and a disciplined team, you can translate drawings into a home that feels both considered and surprisingly calm. Start with the checklist, gather comparable quotes, and tour finished projects to calibrate expectations. Then, when your modules or panels arrive, you’ll be ready to watch an empty foundation turn into a front door—and step through it with confidence.